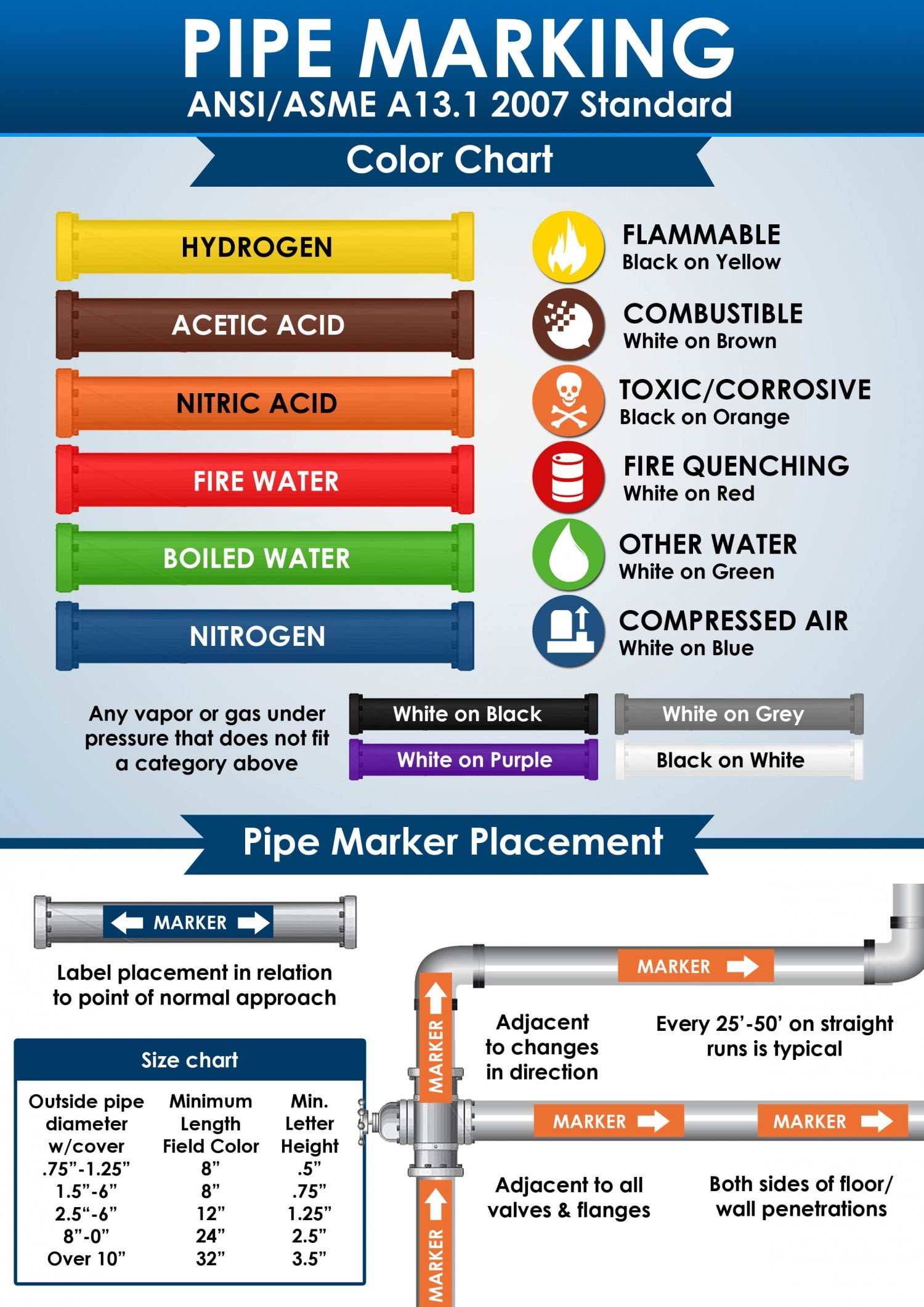

10102014 ANSIASME Pipe Marking Basics. It requires that at a minimum pipe marking must be located on both sides of valves service appliances bulkheads wall and floor penetrations as well as any other place pipe contents identification is needed.

Steel Pipe Manufacturing Processes Mandrel Mill Process Plug Mill Process Electric Weld Pipe Process

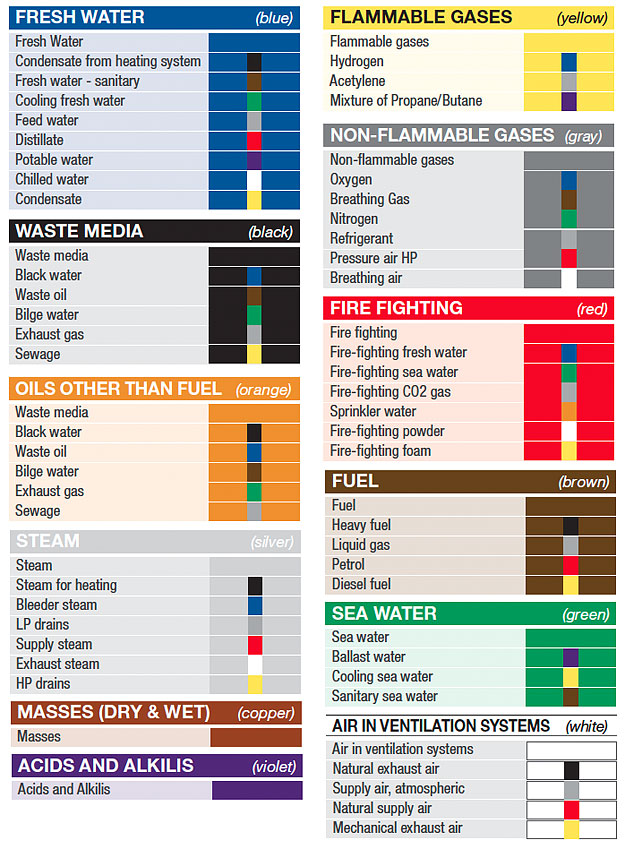

High-hazard low hazard and fire suppression materials.

Pipe line marking procedure. The 67548EEC Directive contains the regulations for the labelling classification and packaging of dangerous substances. To simplify what could be a monumental task the ANSI standard divides pipes into three divisions or hazard classes. Water pipe line marking for bathroom diverter pipe fitting marking----- Support me By its Free -----LIKE COMMENT SHARE SUBSCRIBE Kare aur Ghan.

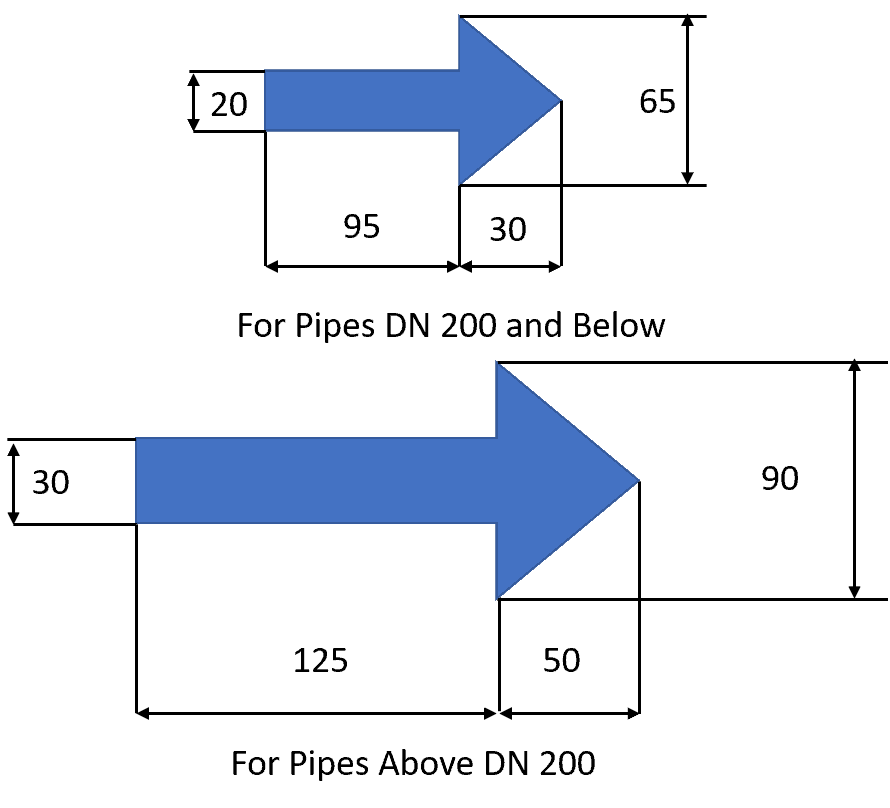

Labels used on pipes must be visible at the most dangerous points such as valves and joints and at reasonable intervals. Pretesting natural gas lines follows an ordered set of steps which allow for satisfactory performance analysis. 600 x 400 mm Order Ref.

52 The documents submittedreferred with this method statement shall be considered as an integral part of this method statement and shall be read in conjunction with the same. The chosen pipe welding procedure is dependent on the choice of pipe its use within the pipeline and the location in which it will be used. To this end kilopascal kPa is adopted as the unit of pressure in calculations.

The BS 1710 pipe marking standard applies to pipes carrying fluids that are located above and below ground. PIPELINE SIZING PROJECT STANDARDS AND SPECIFICATIONS Page 6 of 55 Rev. Mark pipes adjacent to all valves and flanges.

Pipe marking that resists more and 10 year outdoor use. Label color label size and label placement. 01 April 2011 ERW - Electric Resistance Welding mmH 2 O - In adopting the SI System of Units in this Standard it has been tried to satisfy the requirements of API Publication 2564.

Marking of the piping components shall be done as per applicable codes and standards in addition to piping itempart number purchase order number specified in Material Requisition Scope of supply. 1500 micron styrene Size. For example the SAW welding process is generally preferred for offshore arc welding as it is more suitable.

Pipes are cleaned with mechanical cutters that can remove scale buildup and roots. 10122002 To assist with marking pipes the American National Standard Institute ANSI has developed standard A13 1-1996 Scheme for identification of Piping Systems. For the material specified as sour service Low Temperature LT CRYOGENIC in Material Requisition Scope of supply the marking shall include Sour LT and CRYO respectively.

Hazardous material in the pipe c. Now that we know what our pipe labels need to look like and how big they need to be we need to understand where they go. Highlighted below are the key components of pipeline pre-commissioning and commissioning.

01062016 The next step in the lining process is to clean the pipe so that the CIPP liner will adhere to the host pipe. Mark pipes at both sides of floor. 24012013 2 min read.

Mark pipes adjacent to change in direction. Date tag is hung e. Date tag is valid to f.

These pipe markers help communicate information about the contents of pipes and any potential hazards associated with those contents. The tag contains relevant information about the break in including. See page 78 for more information.

Name and signature of Permit Authoriser or Isolating Person placing the tag d. This information assists personnel when carrying out maintenance and emergency personnel when responding to emergencies. 26 PIPELINE MARKING Pipeline marking shall be by use the Break In Location Tag appendix 2.

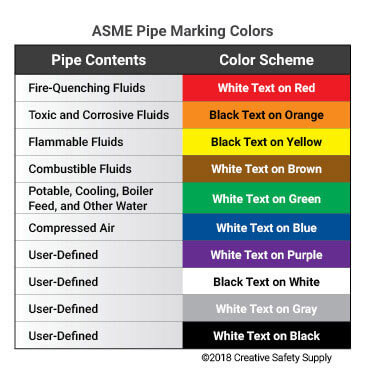

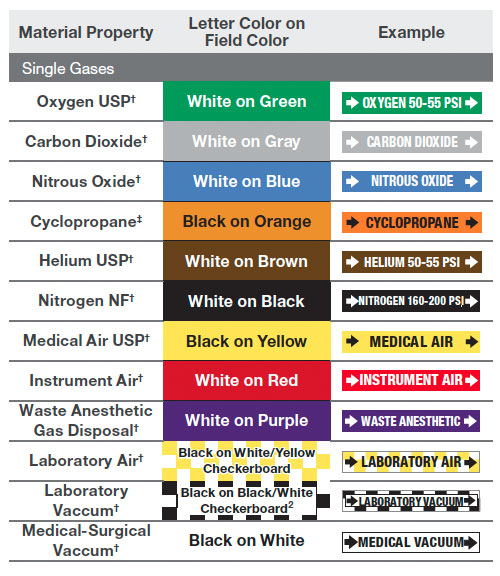

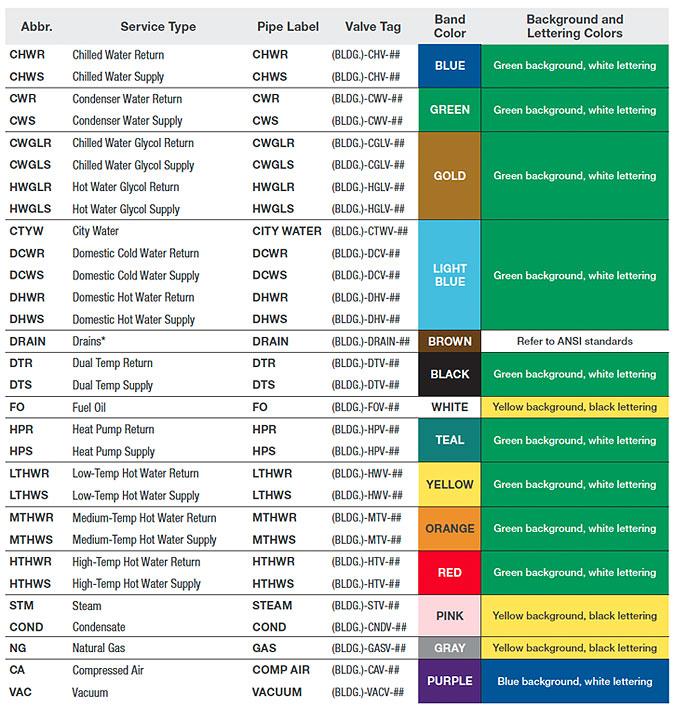

ANSIASME recommendations cover three main aspects of pipe color codes. 19112019 Pipeline Pre-commissioning Procedure. Safety Awareness Poster Poster showing an overview of the legal requirements for pipe marking.

Once the pipe is cleaned the technicians saturate a felt liner with a two part epoxy. The dimensions of the pipe markers must be proportionate to the labelling surface. PROCEDURE 51 Ensure that the document received bear the stamp Issued for Construction and are of latest revision.

Pipe markings come in different colors each bearing a different message or level of significanceThey can be used for both residential and commercial purposes. This material can be used in extremely harsh outdoor environments. Pipe marking is the usage of labels typically color coded to identify the use contents and flow direction of pipes inside of industrial and commercial buildings.

Pipe marking are a very vital tools that can be used to enhance the level of safety in any working environment.

Your Guide To Proper Pipe Marking Creative Safety Supply

Your Guide To Proper Pipe Marking Creative Safety Supply

Steel Pipe Manufacturing Processes Mandrel Mill Process Plug Mill Process Electric Weld Pipe Process

A Guide To Pipe Marking Standards Creative Safety Supply

A Guide To Pipe Marking Standards Creative Safety Supply

Everything You Need About Pipe Marking And Labeling Camcode

Everything You Need About Pipe Marking And Labeling Camcode

Marking Of Steel Pipes Steel Flanges Butt Weld Fittings Valves Fasteners

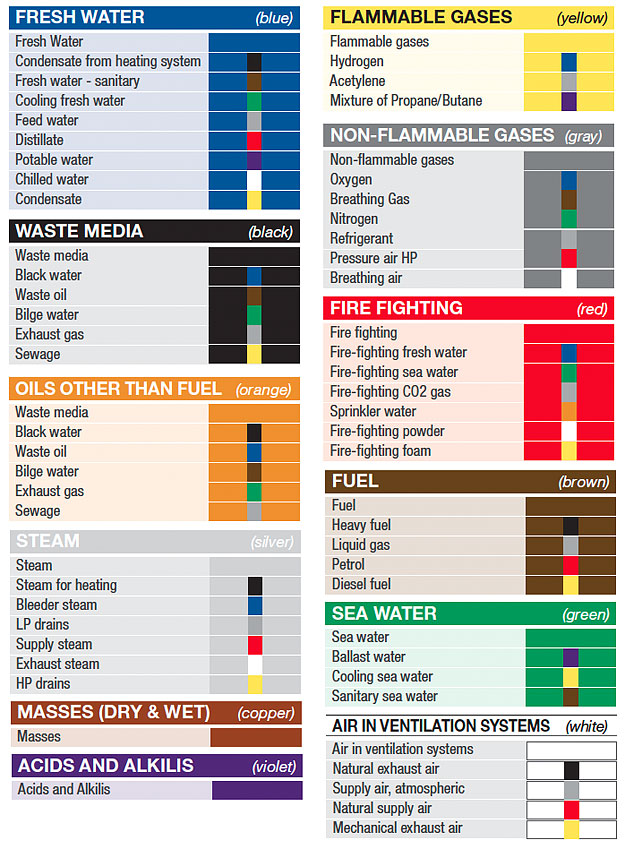

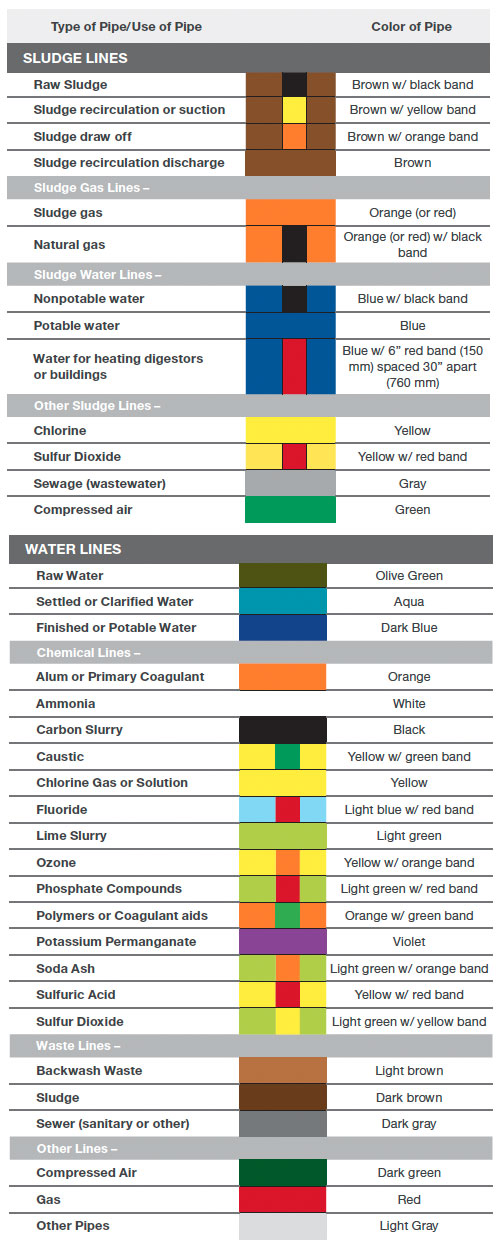

Pipe Color Code Standard And Piping Color Codes Chart

Pipe Color Code Standard And Piping Color Codes Chart

Pipe Marking 101 Basics Of Pipe Safety Graphic Products

Pipe Marking 101 Basics Of Pipe Safety Graphic Products

A Guide To Pipe Marking Standards Creative Safety Supply

A Guide To Pipe Marking Standards Creative Safety Supply

Steel Pipe Manufacturing Processes Mandrel Mill Process Plug Mill Process Electric Weld Pipe Process

Pipe Color Code Standard And Piping Color Codes Chart

Pipe Color Code Standard And Piping Color Codes Chart

Pipe Marking 101 Basics Of Pipe Safety Graphic Products

Pipe Marking 101 Basics Of Pipe Safety Graphic Products

Ansi Asme A13 1 Pipe Labeling Requirements Graphic Products

Ansi Asme A13 1 Pipe Labeling Requirements Graphic Products

A Guide To Pipe Marking Standards Creative Safety Supply

A Guide To Pipe Marking Standards Creative Safety Supply

Everything You Need About Pipe Marking And Labeling Camcode

Everything You Need About Pipe Marking And Labeling Camcode

A Guide To Pipe Marking Standards Creative Safety Supply

A Guide To Pipe Marking Standards Creative Safety Supply

A Guide To Pipe Marking Standards Creative Safety Supply

A Guide To Pipe Marking Standards Creative Safety Supply

Pipe Marking 101 Basics Of Pipe Safety Graphic Products

Pipe Marking 101 Basics Of Pipe Safety Graphic Products

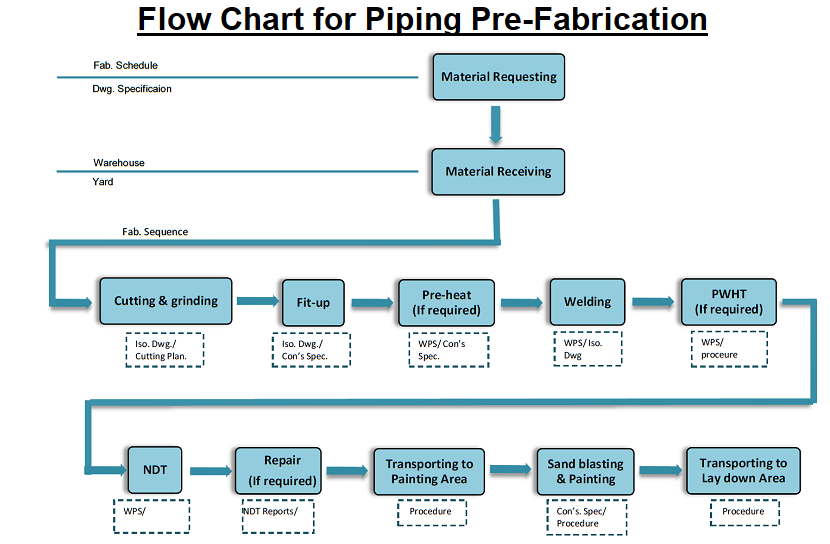

Metallic Piping Fabrication And Installation Method Statement Job Safety Analysis Project Management 123

Metallic Piping Fabrication And Installation Method Statement Job Safety Analysis Project Management 123

Pipeline Inspections Cn Tuv Rheinland

Pipeline Inspections Cn Tuv Rheinland